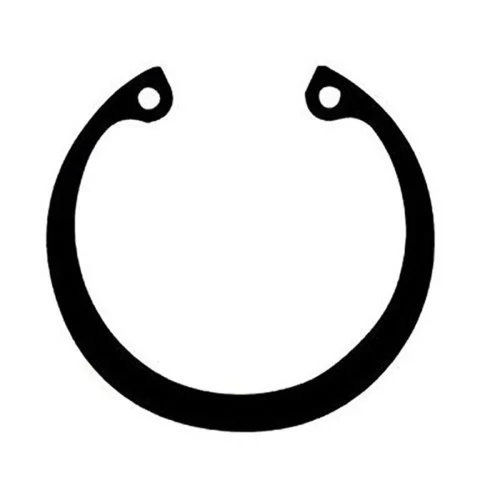

Bearing Preloading Washers

Product Details:

- Length Varies as per washer size, typically 1 mm to 100 mm (outer diameter)

- Size Custom sizes available, common inner diameters: 10 mm to 50 mm

- Width Varies with outer diameter, typically 1 mm to 100 mm

- Height Approximately 0.1 mm to 3 mm (thickness)

- Color Silver / Metallic Grey

- Product Type Bearing Preloading Washer

- Usage Used to provide axial preloading to bearings, reduce vibration, and ensure precise operation in assemblies.

- Click to View more

X

Bearing Preloading Washers Product Specifications

- Bearing Preloading Washer

- Used to provide axial preloading to bearings, reduce vibration, and ensure precise operation in assemblies.

- Custom sizes available, common inner diameters: 10 mm to 50 mm

- Varies as per washer size, typically 1 mm to 100 mm (outer diameter)

- Varies with outer diameter, typically 1 mm to 100 mm

- Approximately 0.1 mm to 3 mm (thickness)

- Silver / Metallic Grey

Product Description

We are a remarkable entity, engrossed in manufacturing and supplying a superior range of Bearing Preloading Washers. These washers are ideal for thrust loading applications made from high carbon tempered spring steel in various machines. Our offered range of washers is precisely manufactured with the help of advanced techniques by making use of high grade raw material in compliance with set industry standards. Besides, we provide these Bearing Preloading Washers in different dimensions as per the exact demands of the clients.

Wave spring washers are used in thrust loading applications for small deflections made from high carbon tempered spring steel.

Features:

- Rugged design

- Excellent strength

- Heat resistance

- Smooth edges

Enhancing Bearing Performance

Preloading washers are crucial for ensuring that bearings perform consistently and without excessive play. By applying the correct axial load, they help decrease vibration and maintain bearing alignment, leading to smoother machinery operation. Their metallic finish complements their robust function, contributing both to aesthetics and durability.

Customizable Dimensions to Suit Diverse Needs

These washers are available in a broad range of custom sizes. With inner diameters typically from 10 mm to 50 mm and strengths tailored for various assembly requirements, users can select the exact specifications needed for their projects. This flexibility allows compatibility with numerous bearing types and mechanical structures.

Versatile Sourcing Across India

Whether you are looking for a trusted dealer, distributor, exporter, importer, manufacturer, retailer, supplier, or trader, bearing preloading washers are widely accessible throughout India. This widespread availability ensures prompt supply for urgent requirements and supports the nations vibrant industrial sector.

FAQs of Bearing Preloading Washers:

Q: How do preloading washers improve the functionality of bearings?

A: Preloading washers apply an axial force to bearings, keeping them in precise alignment. This reduces vibration and eliminates excess movement, resulting in smoother and more reliable operation of mechanical assemblies.Q: What sizes are available for bearing preloading washers?

A: Custom sizes can be supplied, but common inner diameters range from 10 mm to 50 mm, with outer diameters typically between 1 mm and 100 mm, and thickness from about 0.1 mm to 3 mm, ensuring suitability for various applications.Q: In which industries or applications can bearing preloading washers be used?

A: These washers are ideal for applications where stable and precise bearing performance is critical, such as in automotive, manufacturing machinery, robotics, and precision equipment assemblies.Q: Where can I source bearing preloading washers in India?

A: Bearing preloading washers are available from a wide network of dealers, distributors, exporters, importers, manufacturers, retailers, suppliers, and traders throughout India, ensuring easy and reliable procurement.Q: What is the benefit of using preloading washers in assemblies?

A: Utilizing preloading washers stabilizes the bearing, which extends its service life, reduces operational noise and vibration, and maintains the accurate positioning of rotating components within assemblies.Q: What is the process for selecting the right preloading washer?

A: Determine the precise dimensions, bearing type, and load requirements of your application. Consult with a supplier or manufacturer to select or customize a washer that best matches your systems specifications for optimal performance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email