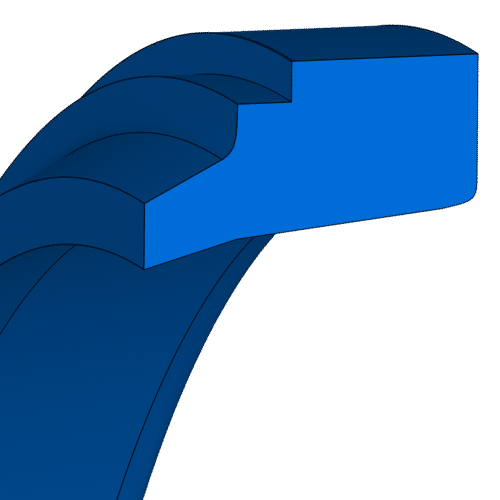

Guide Strips

Product Details:

- Tolerance 0.05 mm

- Material PTFE (Polytetrafluoroethylene)

- Style Rectangular Cut

- Shape Strip

- Application Hydraulic and pneumatic cylinder guidance

- Click to View more

Guide Strips Price And Quantity

- 151.00 - 350.00 INR/Set

- 300-500 INR/Set

- 6 , , Number

Guide Strips Product Specifications

- Strip

- Hydraulic and pneumatic cylinder guidance

- Rectangular Cut

- 0.05 mm

- PTFE (Polytetrafluoroethylene)

Product Description

Our vast market understanding and industry experience enable us manufacture and supply an extensive array of Guide Strips. Well suited for preventing leakage and shock absorption, offered strips are used in pressing machines, automobiles, lift systems and other related devices. Our dedicated team of technical experts make use of latest techniques and superior quality raw material to manufacture these strips in sync with set industry standards. Additionally, these Guide Strips can be availed from us in various sizes.

For Piston or Rod in Hydraulic and Pneumatic Applications made from hard convex with fabric reinforced for Heavy Stressed Hydraulic Application / Bronze-filled PTFE for steel cylinders/ Carbon-filled PTFE for light and non-ferrous metal cylinders.

Features of Guide Strips:

- Ruggedness

- Excellent tolerance

- Withstand high pressure

- Heat resistance

Precision Engineered for Cylinder Guidance

Designed for smooth, reliable performance, these PTFE Guide Strips deliver exceptional support for hydraulic and pneumatic cylinders. Their low-friction surface and dimensional accuracy help reduce component wear and promote efficient motion, making them an excellent fit for demanding industrial environments.

Outstanding Chemical and Electrical Properties

With superior chemical resistance and high dielectric strength, these PTFE strips withstand aggressive substances and provide excellent electrical insulation. Their minimal water absorption and robust density ensure durability and longevity, even when exposed to challenging conditions.

Flexible Sizing for Custom Applications

Available in a variety of thicknesses (1 mm to 10 mm), widths (6 mm to 100 mm), and custom lengths, these guide strips are tailored to fit unique operational needs. The tight manufacturing tolerance of 0.05 mm ensures exact fitment for a wide range of equipment and industries.

FAQs of Guide Strips:

Q: How are PTFE Guide Strips used in hydraulic and pneumatic cylinders?

A: PTFE Guide Strips act as bearing elements that guide the piston or rod in hydraulic and pneumatic cylinders. Their low friction and wear resistance help ensure smooth, precise motion and protect cylinder surfaces from metal-on-metal contact.Q: What benefits do PTFE Guide Strips offer over traditional materials?

A: Compared to conventional materials, PTFE Guide Strips provide outstanding chemical resistance, reduced water absorption, excellent dielectric strength, and very low friction coefficients, leading to less maintenance and extended service life.Q: When should I opt for custom-sized Guide Strips?

A: Custom-sized Guide Strips are ideal when standard dimensions do not suffice or when you need precise fittings to match specific cylinder designs. Our service allows you to select custom lengths, widths, and thicknesses within the available range for optimal performance.Q: Where can these PTFE strips be applied besides hydraulic cylinders?

A: Beyond hydraulic and pneumatic cylinders, these PTFE strips are suitable for use in guiding mechanisms of various machinery, including presses, extrusion lines, and other applications where reduced friction and chemical stability are required.Q: What is the process for ordering Guide Strips with tailored dimensions?

A: Customers can provide required measurements such as length, thickness, and width within the offered range. Upon confirmation, the strips are precision-cut to specifications, ensuring tight tolerances and high surface quality.Q: What are the usage advantages of PTFE Guide Strips in harsh environments?

A: PTFE Guide Strips maintain their properties in chemically aggressive, moist, or electrically charged environments. Their low water absorption and inertness to most chemicals make them suitable for industries like chemical processing, food equipment, and pharmaceuticals.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+